ODM - Discharging agitators RotoEX RWA

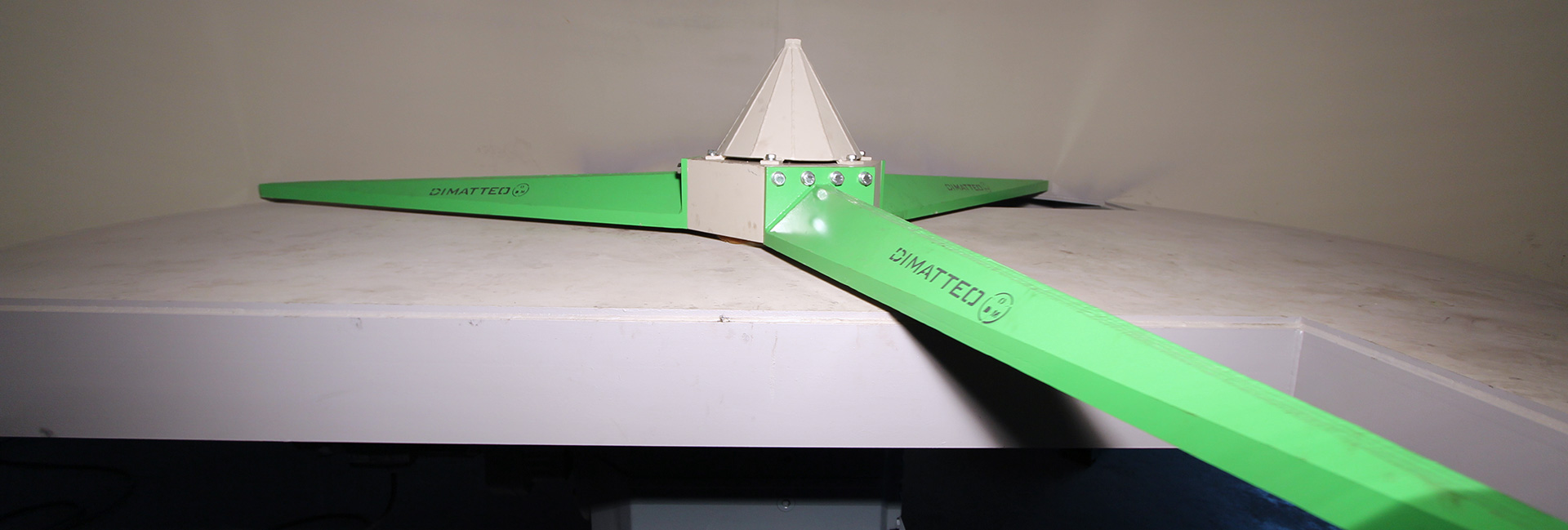

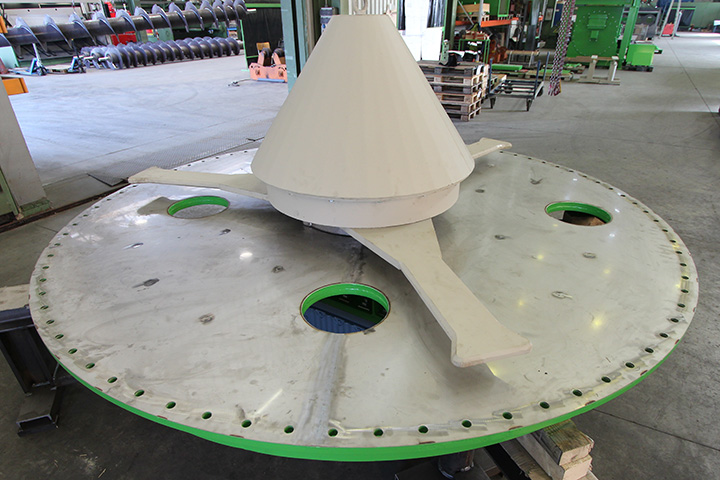

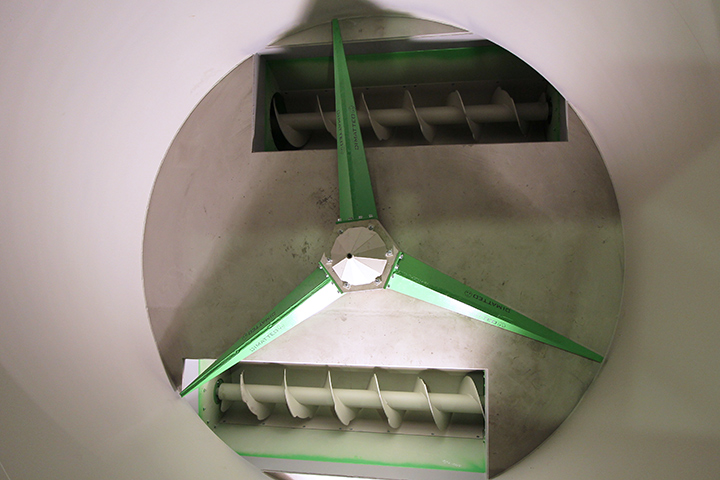

Our tested silo discharging system RotoEX works, depending on the implementation and material properties, on the First-In-First-Out (FIFO) principle, and it is fitted with one or several rotating, robust rotating arms.

These arms undercut the material stack and discharge the material reliably and continuously. Even sticky, poor-flowing materials can be brought to an opening without any problems.

The RotoEX silo discharge system avoids the creation of sedentary zones and material caking during discharge in order to guarantee a continuous material flow.

DI MATTEO offers completely new units from scratch, a replacement of existing facilities, and spare parts for your existing equipment.

Benefits at a glance

- modular construction system

- robust design

- silo diameters of up to app. 6 m

- safe and continuous material discharge

- calm mass flow over the entire cross section with no residual material

- no bridging

- FIFO principle available

- usable with nearly all bulk materials

- all parts easily accessible