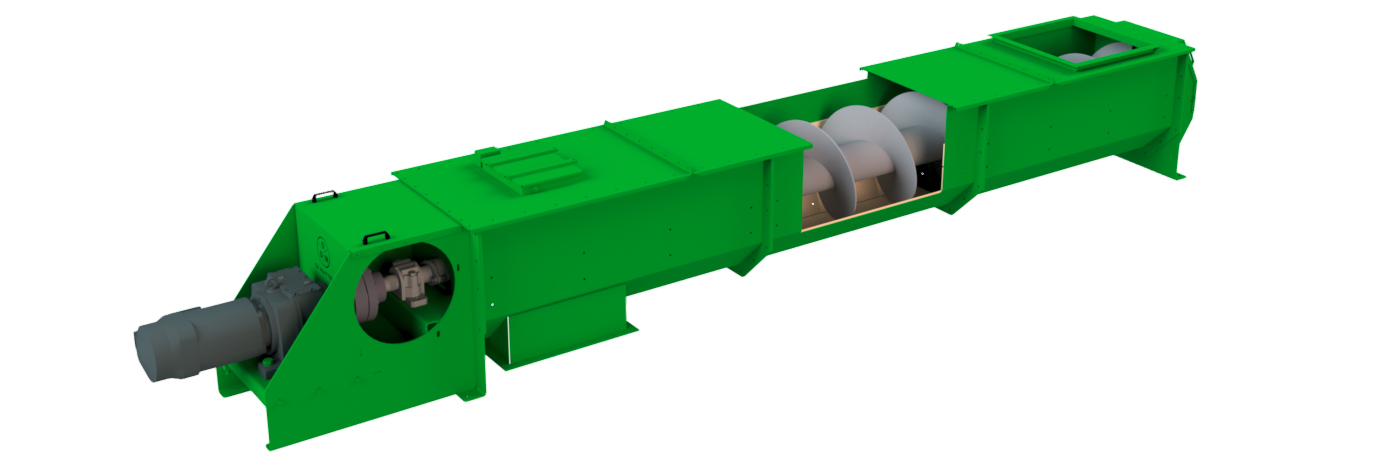

ODM – Screw conveyors

Our screw conveyors provide transport your most varied and idiosyncratic materials, regardless of the angles – from horizontal to vertical.

Screw conveyors (also known as spiral conveyors) are well suited for powdered, granular, small-sized, semi-moist (british spelling w hyphen), and fibrous materials in all branches of industries. Constant improvements to our screw conveyors have have achieved a transport distances of more than 60 metres as well as a capacitance of 1,000 m³/h or more.

Screw conveyors are available in varying models and types. They can be used to discharge, dose, cool, mix, separate, compact, and load, as well as for their primary job of transporting. Depending on your requirements, screw conveyors can be implemented as dust-tight, air-tight or water-tight, thereby not only protecting your product from external influences, but also protecting the environment.

Should you only need to span a short distance of no more than 10 metres, screw conveyors without centre bearings are suitable and meet your requirements as a feeder, unloader, or intermediary conveyor.

DI MATTEO offers completely new units from scratch and spare parts for your existing equipment.

Benefits at a glance

- modular construction with time-tested components

- compact and robust design

- quickly delivered, quickly replaceable

- multiple applications

- minimal susceptibility to failure

- reduced spatial needs

- dust-free and environmentally-friendly transportation

- dust-proof, waterproof, or air-tight

- shock pressure resistant

- wear-resistant

- long durability through additional protection against wear

- use of wear-resistant and low-maintenance central bearings

- heat resistant

- screw conveyor design conforms to ATEX standards

- minimised maintenance efforts

- additional process steps can be integrated, depending on implementation

- continuous operation is possible

- usable at temperatures of up to 500°C with use of appropriate construction materials

Options

Wear protection

Our modular wear protection system ODM - WeartecPRO® consist of a wide variety of wear protection processes and offers the appropriate solution for any application. Special surface coatings, linings or exchangeable inserts extend the service life of the machine and avoid unnecessary production downtimes.

further information…ATEX design

For special applications in potentially explosive areas, we design our machines in accordance with the ATEX directive 2014/34 / EG.

Temperature resistant

Available in a temperature range from -40 C° to + 1,050 °C, depending on the requirements and application.

Equipment

- Cleaning flap

- rotation control

- special paintg

- attachment point

- movable design

- intermediate bearing ODM – DUROGLIDE made of grey-cast iron for the highest demands on service life, lowest possible maintenance effort