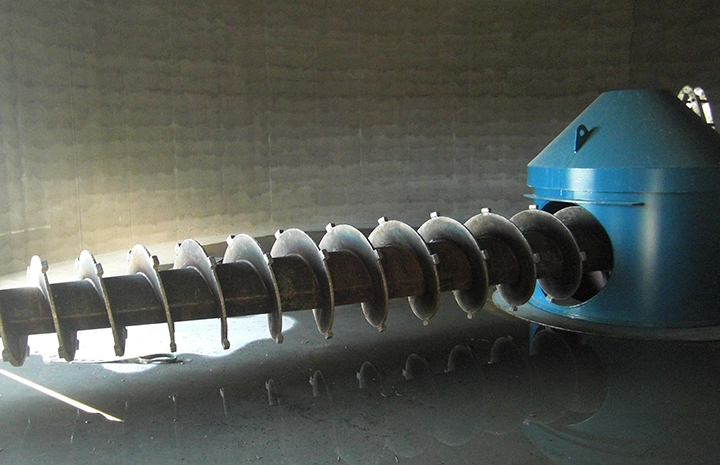

ODM - Rotating extraction screw RotoSCREW ASF

Our RotoSCREW – also known as a feeding screw – for reliable discharging of poor-flowing materials from bunker facilities and silos

The RotoSCREW discharge system empties a bunker’s entire axially-symmetric cross-section by a circular motion and is used in various fields. The procedure is completely accomplished by electric motors.

Depending on your needs, our RotoSCREW can be implemented in various ways and can be individually adjusted to the materials. Under highly demanding conditions, such as with abrasive materials, we offer optional wear-protection which significantly lengthens the operating life of the equipment.

We also have an optional double-screw-schaft design, which can significantly reduce the time needed to discharge large amounts of bulk materials from silos.

DI MATTEO offers completely new units from scratch, a replacement of existing facilities, and spare parts for your existing equipment.

Benefits at a glance

- modular construction system

- robust design

- high availability

- easy assembly and maintenance

- high reliability

- no counter bearings for screw conveyor necessary

- optional wear-protection available