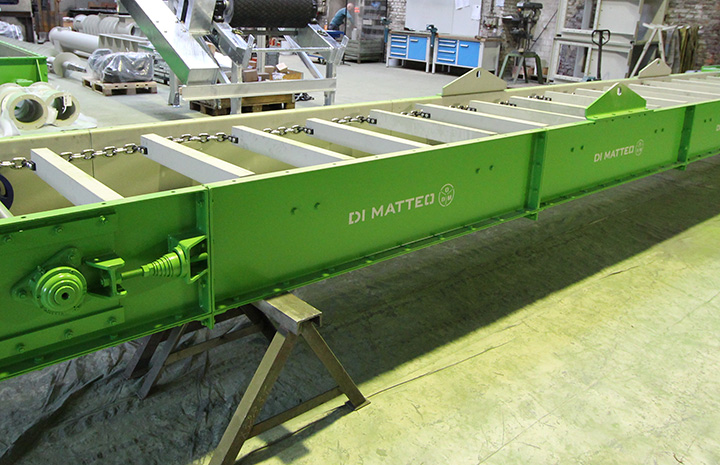

ODM – Drag chain conveyors TKF/KKF

When it comes to continuous conveyors, the drag chain conveyor (also known as the spillage conveyor) is counted among the most tested and important kinds of transport for a wide variety of bulk materials.

Our drag chain conveyors are suited for continual horizontal or steeply inclined transport. Beyond the typical transport needs, they can also be used as discharge conveyors and distribution conveyors with multiple inlets and outlets. The bulk materials are transported cleanly and safely in a closed trough by a seamless conveyor chain with actuators.

Drag chain conveyors are especially known for their low maintenance and robust construction. Their dust-tight and weather-resistant design not only contribute to occupational safety, but also protect your materials and the environment at the same time.

The strength of our drag chain conveyors lies in their high capacity of up to c. 800m³/h and a transport length of up to 150 metres.

Due to the simple operation of the reliable control systems, no specialised personnel are needed for maintenance.

DI MATTEO offers completely new units from scratch and spare parts for your existing equipment.

Benefits at a glance

- materials are gently handled along transport

- resistant to temperature and wear

- high durability

- multiple intake and discharge sites possible

- modular construction with time-tested components

- increased operation reliability

- low operational costs

- minimised servicing and maintenance

- quick delivery of replacement parts

- solid, space-saving, and robust design for continuous operation

- use of wear-resistant and low-maintenance shaft bearings DUROGLIDE®

- use of high quality, drop-forged fork-sprocket chains, round link chains or conveyor chains

- dust-proof, waterproof, or air-tigh

- shock pressure resistant, conforms to ATEX standards

- additional functions such as dosing, cooling and heating are available