WeartecPRO wear-protection solutions for the most diverse types of wear in industries that process bulk materials

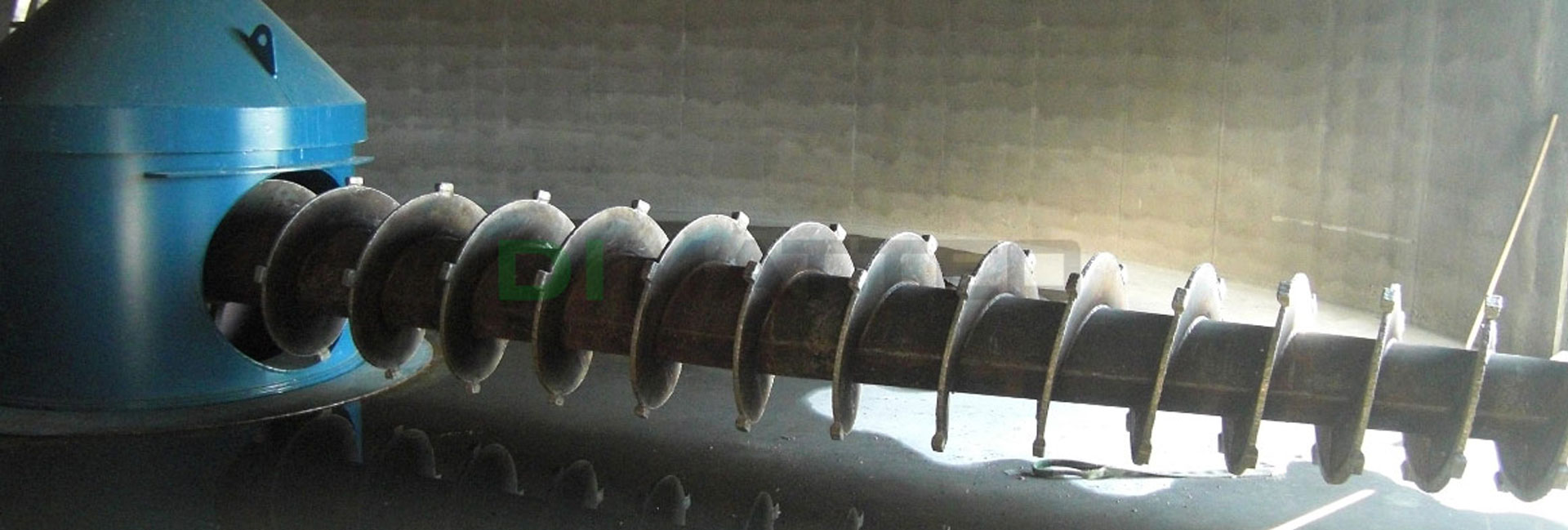

In nearly all industries that process bulk materials, we encounter a wide range of kinds of wear. The wear is often caused by erosive currents, abrasion, and chemical attacks.

Without fail, facility operators and maintenance departments are confronted with the subject of wear-protection, and they must periodically find efficient and long-term solutions for the respective applications.

Facility components frequently react sensitively to regularly-changing material specifications and are, as an example, significantly damaged due to improper discharge of foreign matter.

Wear frequently occurs in bent tubing during pneumatic conveyance of materials, and the results are like turning off the faucet. The end results for you: e.g. when using alternative fuels: No flow, no fuel. No fuel, no energy. We have developed our ODM – QuattroTUBE for this very susceptible and important area.

Wear-protection does not need to be complex or even complicated. Occasionally this is quickly produced through material design (passive wear-protection). Often a few small changes in the process suffice to re-establish a material flow.

We would be glad to inspect your process under the microscope, and get the best possible results from your facilities. Make a free appointment with us.