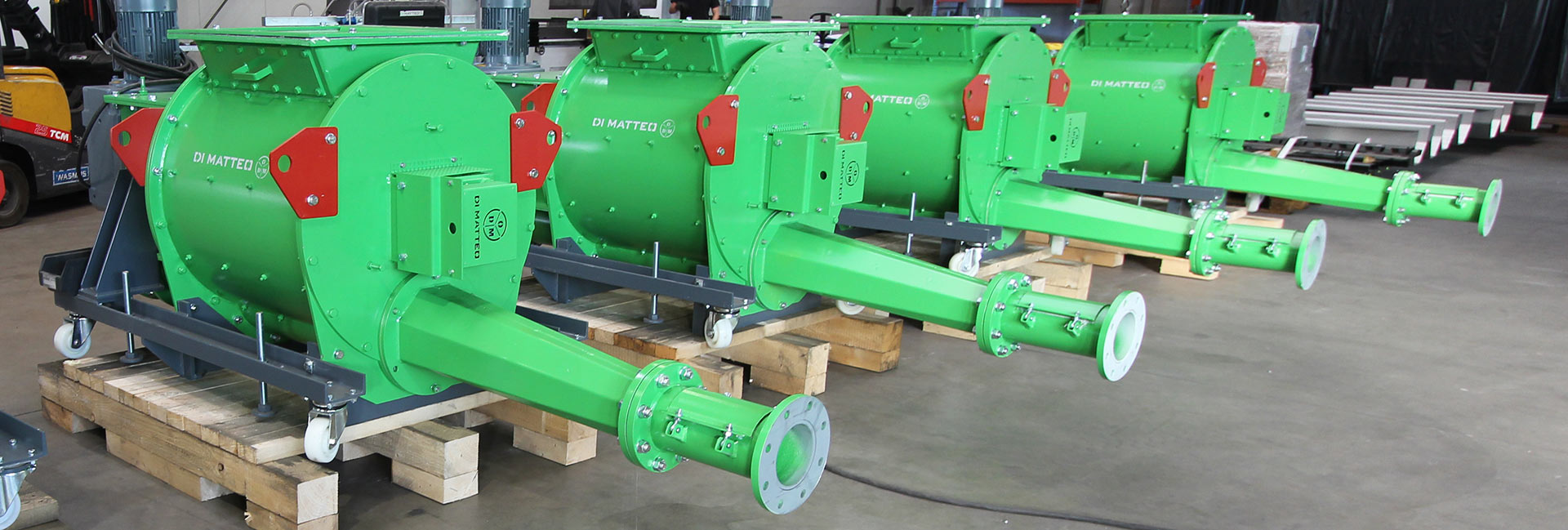

ODM – Injector rotary valves IZS

Injector rotary valves channel the most diverse materials into pneumatic tube conveyor systems and help to bring them into the transport process via an air current.

Since alternative fuels not only have an economical impact, but also save on resources, DI MATTEO has taken it upon itself to develop a pneumatic system for use with these fuels.

In order to help you transport secondary fuels, we offer the best technology available on the market today – a new generation of injector rotary valves.

The feeder rotor can be used with a knife edge, with soft seals, or with both. The patented design, with adjustable injectors, enables a reliable pneumatic conveyance of your materials.

DI MATTEO offers completely new units from scratch, a replacement of existing facilities, and spare parts for your existing equipment.

Benefits at a glance

- modular construction system

- rugged pneumatic transport

- injection of abrasive and hot materials possible

- special implementations for alternative fuels

- compact, robust, and enclosed design

- non-pulsing injection into the process

- maximum flexibility, adjustable for any application

- high quality and wear-resistant materials

- long operating life

- reliable system in low-pressure areas

- highest availability

- easy maintenance

- pressure level can be adjusted during operations

- minimisation of air leakage

- explosion-protected implementation optional